Wet Particle Board. Tips From Professionals

Pressboard and particle board are made up of thin pieces of wood that are pressed together to create large sections. They are often used for furniture. While they are durable and affordable, these pieces are also prone to water damage. If your particleboard gets wet, be sure to try some of our tips.

Wet particleboard:

When particleboard gets wet, it will quickly swell. But if the damage is not extensive, you can still save it. The first step is to assess the damage. If it is not comprehensive, let it dry. You can use several methods for this. When thoroughly dried, sand any swollen areas. Fill holes with wood filler, and sand it to smoothen the area.

In this blog post, I will further explain in more detail how to deal with wet particleboard. Also, what to do with a damaged particle board table, and in-depth how to get the water out of particleboard.

Contents

- 1 Wet Particle Board

- 2 Can You Repair Particle Board?

- 3 How Do You Fix Swollen Particle Board?

- 4 How Do You Fix A Water-Damaged Particle Board Table?

- 5 Will Particle Board Mold If It Gets Wet?

- 6 How You Get Water Out Of Particle Board

- 7 How Do You Fix A Water-Damaged Pressboard?

- 8 The Experiment on Particleboard’s Response to Water Exposure

- 8.1 • Rapid Increase in Thickness

- 8.2 • Damage Impact

- 8.3 • Thickness Reduction with the Drying Process

- 8.4 • Role of Protective Treatments

- 8.5 • Lengthy Drying Process

- 8.6 • Importance of Timely Action and Preventive Measures

- 8.7 • Expert Recommendation

- 8.8 • Identifying the Source of Damage

- 8.9 • Importance of Drying Particle Boards

- 8.10 • Removing Excess Water

- 8.11 • Sanding Swollen Areas

- 8.12 • Removing Damaged Sections

- 8.13 • Using Wood Filler

- 8.14 • Levelling with Sandpaper

- 8.15 • When to Replace the Damaged Particle Boards

- 8.16 • Benefits Of Hiring a Restoration Company

- 8.17 • Free Consultations and Quotes from Rhode Island Restoration

- 9 Assessing and Repairing Water-Damaged Particle Board

- 9.1 • Understanding the Damage Extent

- 9.2 • Speeding Up the Drying Process

- 9.3 • Dealing with Raised or Swollen Areas

- 9.4 • Removing Damaged Sections

- 9.5 • Vacuuming Powdery Sections

- 9.6 • Filling in the Holes

- 9.7 • Striving for an Even Surface

- 9.8 • Achieving a Smooth Finish

- 9.9 • Preventing Future Water Damage

- 9.10 • Replacing Extensively Damaged Sections

- 9.11 • When to Seek Professional Repair Services

- 10 Particle Board vs. Hardwood Cabinets: A Comparative Analysis

- 10.1 • Particle Board Cabinets: The Budget Option

- 10.2 • The Vulnerability of Particle Board in Wet Environments

- 10.3 • Sealing Particle Board: A Short-Term Solution

- 10.4 • Signs of Water Damage and Repair Challenges

- 10.5 • Hardwood Cabinets: The Durable Choice

- 10.6 • The Case for Fully-Sealed Hardwood Cabinets

- 10.7 • Particleboard: Waterproofing and Maintenance

- 10.7.1 – Understanding Particleboard and Water Damage

- 10.7.2 – Importance of Waterproofing

- 10.7.3 – Sealing Approaches for Particleboard

- 10.7.4 – Preparing Particleboard for Sealing

- 10.7.5 – Applying the Sealer

- 10.7.6 – After Sealing

- 10.7.7 – Handling Wet Particleboard

- 10.7.8 – Replacing Severely Damaged Board

- 10.7.9 – Gluing and Finishing Particleboard

- 10.7.10 – Sealing MDF (Medium Density Fiberboard)

- 11 Understanding Particle Board Composition

- 11.1 • The Impact of Water on Particle Board

- 11.2 • Dangers of Leaks for Particle Board Furniture

- 11.3 • Can Sealing Particle Board Help?

- 11.4 • Expected Lifetime for Particle Board Furniture in Wet Areas

- 11.5 • The Superiority of Hardwood Cabinets in Humid Environments

- 11.6 • The Value of Strategic Planning and Expert Consultation

- 11.7 • Recommendation and References

- 12 Factors Impacting Water Damage in Particleboard

- 12.1 • The Role of Humidity and Water Vapor

- 12.2 • Impact of Particleboard Composition

- 12.3 • Influence of Surface Treatment

- 12.4 • Comparing the Effects of Direct Water Contact and Humidity Exposure

- 12.5 • The Role of Exposure Duration and Additional Stress

- 12.6 • Types of Damage

- 12.7 • An Experimental Study on Water Exposure and Particleboard Drying

- 12.8 • The Efficiency of Water-Resistant Protection

- 12.9 • Significance of Timely Measures and Protective Measures

- 13 Characteristics of Particle Board

- 13.1 • Where to Install Particle Board

- 13.2 • The Use of Screws or Nails in Particle Board

- 13.3 • Dealing with Water-Damaged Particle Board

- 13.4 • Repairing Water-Damaged Particle Board

- 13.5 • Speeding Up the Drying Process for Wet Particle Board

- 13.6 • Cleaning Particle Board to Kill Mold

- 13.7 • Rectifying Warped Particle Board

- 13.8 • Life Expectancy of Particle Board

- 13.9 • Identifying and Fixing the Source of Water Damage

- 13.10 • Potential Sources of Water Damage

- 13.11 • Hiring a Restoration Company

- 13.12 • Drying Particle Boards before Repair

- 13.13 • Removing Excess Water and Expedited Drying

- 13.14 • Sanding Swollen Areas

- 13.15 • Cutting Out Damaged Areas

- 13.16 • Filling Holes with a Wood Filler

- 13.17 • Using Sandpaper for Smoothness

- 13.18 • Applying a Finishing Coat

- 13.19 • Replacing Particle Board

- 13.20 • Contacting Restoration Specialists

Wet Particle Board

I have seen a lot of water damage particle board and pressboard, and many people make the mistake of throwing it out when they could save it. Here are some of my tips for saving wet particleboards:

- Do not wait: Work quickly to dry off the particle board so you can remove the water before it has a chance to soak deep inside the particleboard.

- Dry completely: Allow the wood to dry completely before working on it.

- Sand: Try to sand it before removing any damaged areas to reduce the amount of work you have to do.

- Sealant: Use a sealant to protect the wood once you have completed repairs.

- Store inside: Don’t store your particle board or pressboard outside or in any area where it could get wet or be exposed to moisture.

- Check for mold: If your particleboard or pressboard is wet, be sure to check for signs of mold and mildew growth. Remove it completely before trying to make repairs.

Can You Repair Particle Board?

You can repair particle board, but a specific method must be used for it to be fixed properly. Particleboard is not as sturdy or durable as other types of wood, and it will swell and even fall apart if it gets wet. Knowing how to repair the particle board is essential and will determine how successful the repairs are.

In the next paragraph, the method will be explained in detail.

How Do You Fix Swollen Particle Board?

If you find that your particleboard is swollen, there’s a good chance it has been damaged by water. It can be fixed, but it will take some patience and the following steps.

● Step 1: Assess The Damage

Look for signs of water damage and make sure the particle board is not wet. If the particle board is swollen, it may still be wet. You will not want to do anything if the particle board is still wet.

● Step 2: Dry the particleboard

If the damage is not extensive, the next step is to let the particleboard dry. You can leave it in a well-ventilated dry area or use a fan and/or dehumidifier to speed up the process.

● Step 3: Sand It

If the particle board is only slightly swollen, you may be able to sand it down to fix it. If there is a lot of swelling, you might need to cut out the damaged area.

● Step 4: Apply Wood Filler

If you did have to remove some of the swollen portions of the particleboard, you would want to add wood filler to level it out. Apply the wood filler to the particle board and allow it to dry thoroughly.

● Step 5: Sand It Again

You will need to go over the particle board again to smooth it all down and work on the part that was filled in with the wood filler. Once the surface is smooth, you can paint, stain, or leave it how it is.

How Do You Fix A Water-Damaged Particle Board Table?

If you have a table made out of particle board, it is always possible to get wet. Before you throw it away, there are some things you can do to save it. Follow these steps to fix the particleboard table properly.

● Step 1: Dry The Area

Before you can tell how bad the damage is, you will want to dry it. The best way to do so is to let it dry naturally. You can set it outside in the sun as long as it won’t rain or be exposed to extreme weather. You can also speed up the process by using a hairdryer to dry the wet area or adding towels to the wet area and then removing them when they have soaked up all the moisture.

● Step 2: Remove The Damaged Areas

You will need to inspect the table and then cut out any damaged portions. This is any part that seems to be swollen or rotten. You can use a knife to cut out these areas.

● Step 3: Fill In The Missing Areas

Use a good quality wood filler to fill in the holes or any spots you had to remove. You will want to fill up the empty areas until the wood glue reaches the top of the table and creates a smooth and level surface. Allow it to dry for several hours.

● Step 4: Sand It

Once the wood glue is dry, you will want to sand down the entire area. You can do this with a buffer or sandpaper. Be careful not to sand too aggressively, as you may remove too much of the wood filler and have to restart the process.

● Step 5: Stain Or Paint

If you plan to paint or stain the table, you will want to do so once you have finished sanding it. This will finish the table. You can also apply a sealant to help protect the table from future water damage.

Will Particle Board Mold If It Gets Wet?

Particleboard is the perfect place for mold and mildew to grow. If it gets wet or even damp, mold can start to grow quickly. It can be hard to see mold growth because it can start between the particles. You may even smell the mold or mildew before you see it on the particleboard. Mold and mildew can be removed.

How You Get Water Out Of Particle Board

If you notice that your particleboard is holding water, you can do a few things to get the water out of it. The method you choose should be based on the amount of water that has soaked into it and how long it has been wet. Here are some methods to help you remove the water from the particleboard.

● Get Water Out Of Particle Board: Hair Dryer

If you have a hairdryer, you may be able to force some of the water out by using it to direct heat to the wet area of the board. This will help to absorb some of the wetness and help dry the particleboard much faster.

● Get Water Out Of Particle Board: Towels

If there is water pooled or puddled on the particleboard, you will need to remove it as soon as possible. The faster you remove the water, the less it will soak into the particleboard. You can use towels or rags to soak up the water. You can leave the towels in place for a few minutes and then remove them and switch them out for dry towels if needed.

● Get Water Out Of Particle Board: Fans

You can point a fan at the particle board to help dry it out. The fan will help the air circulate around the particleboard and pull some of the water out of the boards. This can be effective if a large area of the particleboard has been damaged.

● Get Water Out Of Particle Board: Open The Windows

If the particle board is inside, you might want to open up the windows in the room to allow some air to circulate. This will make it easier for the table to dry out and could remove moisture from the room that could soak back into the windows. It can also reduce the chance of mold growth.

● Get Water Out Of Particle Board: Dehumidifier

Using a dehumidifier can help remove the water and moisture from the particle board more quickly. You can use a residential dehumidifier, but I always recommend renting commercial dehumidifiers. They can remove a lot more water per hour than a residential dehumidifier.

A dehumidifier pulls in the moisture from the air and dries it out to release dry air back into the room. For even more effective removal, use a dehumidifier together with a fan.

How Do You Fix A Water-Damaged Pressboard?

Pressboard and particle board are very much alike, and both of them can easily be damaged if they get wet. It’s best to avoid bringing liquids around it or storing it outside where it can get wet. If your pressboard does show signs of water damage, follow these steps to fix it:

● Step 1: Dry It

Allow the pressboard to dry thoroughly before you start to work on it. You can dry it with a hairdryer or fan or allow it to air dry for several hours or days, depending on how much water has soaked into it.

● Step 2: Buff Or Remove Swollen Areas

If you notice that the pressboard is swollen, you will need to remove it or buff it. You want the pressboard to be smooth and level. If you need to remove it, you can use a knife to cut out the damaged areas. If you are going to sand it, you can use sandpaper.

● Step 3: Fill In The Holes

If you did need to remove any areas of the pressboard, you would need to fill them in to make them level. You can use a wood filler to do this. Allow it to dry thoroughly and buff it again to ensure it’s all flat and even with the rest of the pressboard surface.

● Step 4: Finish

If you plan to use the pressboard for something and need to paint and stain it, do it now. You can also apply a sealant to help protect the pressboard from spills and weather.

The Experiment on Particleboard’s Response to Water Exposure

In an intriguing experiment, a standard particleboard was submerged fully in water for a complete 24-hour period and then subjected to a drying cycle of 14 days.

The main objective of the experiment was to closely observe the swelling process of the particleboard and its alteration in thickness during and after moisture exposure.

• Rapid Increase in Thickness

The experiment yielded fascinating results. As the particleboard was exposed to the water, the thickness increased at high speed, particularly during the initial hours. This manifested the swift absorption of water by the particles, which in turn led to the expansion or swelling of the board.

By the end of 24 hours, the particleboard had reached its maximum thickness.

• Damage Impact

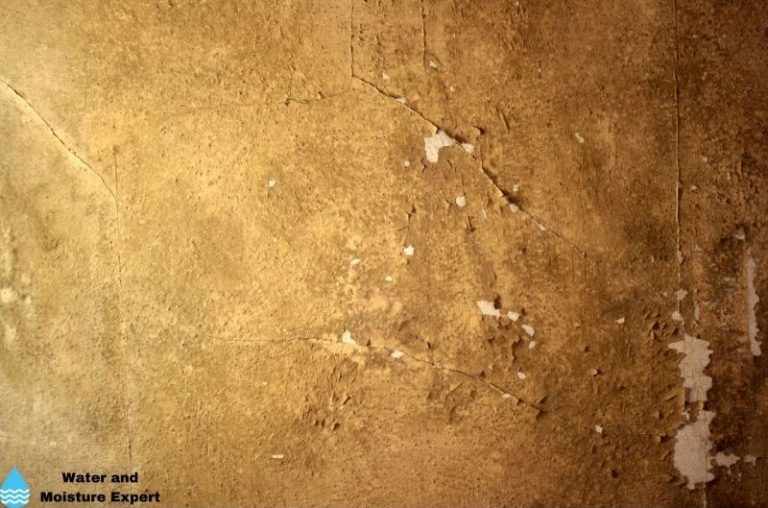

There was a significant development approximately 6 hours into the water exposure. It was deduced that beyond this point, the impact of the water exposure on the particleboard became irreversible.

That is, the damage inflicted on the particleboard was permanent and it became incapable of reverting to its original thickness or state. This highlights the potential magnitude of water damage on such materials, particularly if left untreated for prolonged durations.

• Thickness Reduction with the Drying Process

During the drying phase, which extended over a span of 14 days, the particleboard’s thickness began to diminish gradually. As the water was gradually removed from the particleboard, the thickness reduced to a point where it was marginally less than its original thickness.

• Role of Protective Treatments

Examining the potency of protective treatments in this context, the experiment results underscored their importance. Protective measures such as the application of paint on the surface of the particleboard can significantly impede the process of water absorption and, subsequently, the damage.

• Lengthy Drying Process

Subsequent to the water submersion phase, the drying process necessitates a substantial quantity of time, extending up to two weeks. This extended drying period is attributed to the particleboard’s durable construction, as the water has to be fully evaporated from each particle of the board.

• Importance of Timely Action and Preventive Measures

Recognizing the irreversible damage inflicted by prolonged water exposure to the particleboard, the importance of timely action becomes evident. Immediate measures to prevent further water penetration crucially protect the particleboard from getting permanently damaged.

The application of protective coatings can significantly enhance the lifespan of particleboard against moisture exposure.

• Expert Recommendation

Based on the experiment, it is recommended to apply a protective coating or sealant onto the particleboard, especially if it is expected to be exposed to moisture or water.

This preventive measure can effectively mitigate the impact of swelling, thereby safeguarding the particleboard against water damage.

To know more about preventive treatments and their applications, refer to this educational article on the U.S. Forest Products Laboratory website. It provides in-depth details about protective treatments for wood-based products like particleboard, offering valuable insights for effective moisture damage prevention.

• Identifying the Source of Damage

In dealing with water damage on particle boards, the first critical step is to identify the source. It could be anything from burst pipes to problematic roof leaks. Properly determining the cause of the damage not only helps in addressing the immediate issue but also in preventing future water damage.

• Importance of Drying Particle Boards

After the damage source is found and fixed, it’s essential to ensure that all the particle boards are completely dry. Any residual water can lead to further damage and instigate the growth of unpleasant stuff like mold and mildew.

• Removing Excess Water

Efficiently drying out the water-damaged particle boards is achievable using items such as a hairdryer and towels. Concentrated heat from the hairdryer can expedite the drying process, while the towels can absorb any excess water left on the surface.

• Sanding Swollen Areas

Swollen spots on particle boards are common after water exposure. These areas can create an uneven surface that needs to be leveled before proceeding with further repairs. An effective way to achieve this is by sanding the swollen spots to restore uniformity.

• Removing Damaged Sections

In some cases, parts of the particle board can be so damaged that they may need to be cut out entirely. This can typically be accomplished using something as simple as a knife or any sharp tool. However, it’s crucial to ensure that you’re only removing the damaged parts to prevent wastage.

• Using Wood Filler

After removing damaged parts of the particle board, there are often resulting holes left that need to be patched. A good-quality wood filler is incredible for this job. You can use a putty knife to apply the filler to the holes and gently smooth out the excess to blend with the rest of the surface.

• Levelling with Sandpaper

Post the filling process; you’ll need to sand the surface down to ensure it’s totally level and smooth. You can use medium or fine-grit sandpaper to effectively level the surface. This creates an even, smooth surface, ready for final polishing.

• When to Replace the Damaged Particle Boards

Although many water-damaged particle boards can be repaired, some may be too damaged and could require replacement. This typically applies when the repair process is time-consuming or the results are unsatisfactory.

• Benefits Of Hiring a Restoration Company

When dealing with extensive water damage at home, it could be beneficial to hire a professional restoration company. They can handle reparations effectively and guarantee the eradication of any mold damage.

Brands like Rhode Island Restoration, for instance, offer dedicated particle board water damage repair services.

For more extensive information on mold and its related issues, you can refer to the United States Environmental Protection Agency’s mold resources available here.

• Free Consultations and Quotes from Rhode Island Restoration

Rhode Island Restoration provides free consultations and quotes for their service, which can be of great help in planning the repair or replacement costs. Their experience in this field ensures professional, quality service that guarantees satisfactory results.

Following these series of steps can efficiently repair water-damaged particle boards in your furniture or cabinets.

However, its recommended to engage with professionals in the event of extensive damages for best results. Staying proactive in maintaining and checking your fixtures can also prevent severe water damage.

Assessing and Repairing Water-Damaged Particle Board

• Understanding the Damage Extent

The initial step in addressing water-damaged particle boards is assessing the extent of the damage. It’s crucial to accurately gauge how much of the board is affected before moving forward with any repairs. Overlooking sections with water damage could lead to more extensive problems down the line.

• Speeding Up the Drying Process

Once the damage has been assessed, use a hairdryer or fan to speed up the drying process. Bear in mind that completely drying the damaged particle board before proceeding with repairs is crucial. A rushed drying process can worsen the damage and create even more costly repairs.

• Dealing with Raised or Swollen Areas

After the particle board is thoroughly dried, you will need to tackle any raised or swollen sections. Use a piece of sandpaper to sand these areas until they are back to their normal shape and size.

• Removing Damaged Sections

Following this, look for any damaged sections of the particle board. These sections should be carefully removed using a knife. When performing this task, exercise caution to avoid causing more harm to the board or to yourself.

• Vacuuming Powdery Sections

Following the removal of damaged sections, you might notice some powdery sections on the particle board. Vacuuming these sections ensures that you remove any lingering water damage, creating a clean and smooth surface for repairs.

• Filling in the Holes

Now that the damaged sections are removed, you will likely need to fill in the holes left behind. Use a wood filler and follow the instructions provided on the package. Apply the filler carefully to ensure the holes are adequately filled.

• Striving for an Even Surface

After applying the wood filler, remove any excess to create an even surface. You can use a scraping tool for this task. The end goal is to ensure the repaired areas blend in with the rest of the particle board.

• Achieving a Smooth Finish

Once you have an even surface, the next step is to give your repairs a smooth finish. Fine-grit sandpaper is perfect for this task as it gently smooths the surface without causing any damage.

• Preventing Future Water Damage

After successfully repairing the water-damaged particle board, it is time to prevent future damage. Applying a waterproof seal can protect the particle board from future water-related issues. You can find various waterproof seal brands online or in local stores.

• Replacing Extensively Damaged Sections

In situations where the water damage is extensive, consider replacing the affected sections with new particle boards. This step might be more costly but is often necessary to maintain the integrity and functionality of your furniture or flooring.

• When to Seek Professional Repair Services

There are situations where water damage is so extensive that it requires professional repairs or installation services. When faced with such situations, do not hesitate to seek professional help. I recommend The Institute of Inspection Cleaning and Restoration Certification (IICRC) as a good starting point in identifying certified professionals near you.

Remember, balancing the cost of repairs and the value of the item is key. Sometimes, replacing an entire piece of furniture might be more cost-effective than repairing a severely water-damaged particle board.

Particle Board vs. Hardwood Cabinets: A Comparative Analysis

• Particle Board Cabinets: The Budget Option

Among the myriad choices in home decor available today, particle board has emerged as a popular alternative to hardwood for cabinets. Crafted from wood scraps and shavings, this product offers a cost-effective option for homeowners.

However, it is imperative to understand that this economical solution does come with its own set of drawbacks.

• The Vulnerability of Particle Board in Wet Environments

The major disadvantage when opting for particle board cabinets is their susceptibility to moisture. The mere contact with water can cause permanent damage, leading to swelling, deformation, and even structural instability.

Especially in humid environments, such as bathrooms, these cabinets are prone to quickly lose their shape, with shelves buckling easily under the weight of their load.

The US Environmental Protection Agency EPA even advises caution while using products that are susceptible to moisture, as it can affect the quality of indoor air.

• Sealing Particle Board: A Short-Term Solution

Some may argue that sealing particle boards can help mitigate these issues. Indeed, a sealed surface may offer some protection, but it does not make the board as resilient as hardwood. Particle board, even when sealed, remains vulnerable to scratches and dents.

A scratch or small hole, albeit minor, poses a significant risk as it compromises the integrity of the seal, paving the pathway for moisture penetration. Thus, regardless of the seal, particle board is likely to suffer from water damage over time.

• Signs of Water Damage and Repair Challenges

Herein lies another problem – the gradual degradation of particle board due to moisture exposure is not always apparent.

Over the long term, subtle changes such as swelling, warping, and occasional bubbling may occur. These signs are usually an indication of moisture entering the material via holes or scratches, causing the particle board to deteriorate.

One should also note that repairing particleboard cabinets is particularly challenging. Joints warp, thus realigning shelves and drawers becomes an uphill task – further proof that this material, despite its low cost, may not always be the more economical option in the long run.

• Hardwood Cabinets: The Durable Choice

Unlike particle board cabinets, hardwood cabinets are naturally much more durable. They can withstand much harsher conditions and circumstances. They do come with a higher upfront cost, but this investment pays off in durability and longer lifespan.

Whether it’s in terms of robustness, resistance to wear and tear, or sheer lifespan, hardwood cabinets are second to none. These cabinets are engineered to last for decades and are particularly adept at enduring the challenges of wet areas.

• The Case for Fully-Sealed Hardwood Cabinets

Considering all factors, investing in fully sealed hardwood cabinets tend to provide the best value for money, especially in wet areas. A sealed hardwood cabinet offers the perfect blend of strength, longevity, and resistance to moisture, making it a durable and cost-effective choice.

As an expert in cabinetry, I highly recommend opting for fully-sealed hardwood cabinets. Their exceptional longevity and strength make them a fitting choice for areas such as the bathroom and kitchen that have high humidity levels.

They are truly an investment that will continue to provide utility and aesthetics while resisting damage over a span of multiple decades.

• Particleboard: Waterproofing and Maintenance

– Understanding Particleboard and Water Damage

Many of the materials we use in home construction today are prone to wear and tear, and this is especially true for particleboard. This common, cost-effective material often finds its way into our homes via cabinets and shelves. However, the problem with particleboard is that it is not waterproof.

The compacted wood chips that make up the core of the product quickly absorb moisture. This absorption can lead to unattractive and potentially damaging consequences such as cracking, warping, or swelling.

– Importance of Waterproofing

Given the nature of the material, it is crucial to apply some form of waterproofing to your particleboard surfaces. Proper sealing prevents water absorption and minimizes damage.

By waterproofing particleboard, you effectively increase its lifespan and enhance its durability, especially in humid conditions.

– Sealing Approaches for Particleboard

When it comes to sealing and waterproofing the particleboard, there are a few solutions to consider. Polyurethane (oil-based or water-based) and epoxy resin are two typical products you can use. Each of these sealers comes with its advantages and tends to work well in different scenarios.

Polyurethane Sealer

Polyurethane is exceptionally resistant to water, heat, and chemical exposure, making it an excellent choicer for indoor applications. Furthermore, the glossy finish that polyurethane leaves behind can also elevate the look of the particleboard.

Epoxy Resin Sealer

Epoxy resin, on the other hand, provides a tougher, more resistant coating. It is better suited to areas with extremely high humidity or more demanding conditions.

– Preparing Particleboard for Sealing

Regardless of which sealer you choose, certain steps must be taken before application. The first step is to ensure the surface is as clean as possible. Any dust or dirt will interfere with the sealing process and potentially weaken the results.

So, start off by cleaning the particleboard surface thoroughly. Dust it off, use the standard household cleaner if necessary, and ensure the board is dry before moving on to the application.

– Applying the Sealer

Once cleaned, the particleboard is ready to be sealed. Typically, use a brush or roller for this process, and apply the sealer in a thin, even coat. Always ensure to follow the manufacturer’s instructions when applying the sealer.

When in doubt, a thin coat is always advisable as it will dry evenly and function better. Excess sealer could cause pooling and slow the drying time.

– After Sealing

When the first coat is done, let the sealer dry completely before applying additional coats. The drying time between coats ensures a solid layer to protect your particleboard. If you’re sealing a particleboard cabinet, it’s essential to cover the entire surface.

Consider sealing the unseen parts, as they can absorb moisture and compromise the board’s integrity.

– Handling Wet Particleboard

In an unfortunate event, if the particleboard gets wet, it’s likely to swell and cause further issues. So, you may need to do damage control. Some light sanding and a reapplication of the sealer should resolve minor swellings. Sanding removes the swollen areas and prepares the wood for new sealer.

– Replacing Severely Damaged Board

For severe water damage or extended exposure to water, the particleboard may need to be replaced entirely. Particles, especially those in constant contact with water, are not built to retain their structural integrity under such conditions.

– Gluing and Finishing Particleboard

Unlike solid wood, particleboard cannot be glued on top, as this will likely damage its surface. Oil-based finishes such as polyurethane or Danish oil are recommended for a durable and attractive finish.

– Sealing MDF (Medium Density Fiberboard)

Polyurethane not only seals particleboard but can also be used to seal MDF (Medium Density Fiberboard). This helps prevent water damage and makes MDF viable for a wider range of applications.

It’s important to understand that every material has its strengths and weaknesses. Having an awareness of these factors will help us use the right precautions and treatments to deliver longer-lasting results.

For more information on the care and maintenance of particleboard, visit Cornell University’s Cornell Cooperative Extension section for more home improvement tips.

Understanding Particle Board Composition

Particle board, a common choice for budget-friendly cabinetry, is fabricated from wood scraps and shavings, which are subsequently bound together using adhesive glue.

Due to its unique composition, particle board is not as robust as hardwood. Furthermore, it has a high vulnerability to water and moisture, largely due to the loose bonding from the scraps and shavings.

• The Impact of Water on Particle Board

The porosity of the particle board makes it behave much like a sponge. It readily absorbs water. As such, when particle board furniture comes into contact with water, debilitating damage can occur swiftly and is often permanent.

Particularly, particle board cabinets located in wet areas are prone to lose their structure, while shelves made of this material can buckle easily under strain.

• Dangers of Leaks for Particle Board Furniture

Leakages in particle board cabinets typically necessitate a full substitution of the affected boards. Water seeping in particle board permeates the material, causing irreparable damage, hence rendering simple repairs impossible.

This moisture intrusion leads to significant structural integrity loss and deteriorates the cosmetic appearance.

• Can Sealing Particle Board Help?

While sealing particle boards can somewhat lessen the probability of water damage, the end result is still a risky proposition compared to other, more durable materials. Sealed particle board isn’t as tough and bears a high susceptibility to scratches and dings.

Even a minor deep scratch or minuscule hole can permit moisture infiltration. Over time, this moisture ingress causes the particle board to swell, eventually leading it to warp.

• Expected Lifetime for Particle Board Furniture in Wet Areas

The limitations of particle boards in wet areas can lead to frequent repairs or replacements within a relatively short timeframe.

Often, the lifetime of particle board furniture in such environments ranges between three to five years. As a result, any initial cost savings could be offset by the expenses involved in subsequent repairs or replacement.

• The Superiority of Hardwood Cabinets in Humid Environments

In contrast, hardwood cabinets, when fully sealed, prevail as the superior choice for areas prone to moisture or humidity, including those susceptible to leaks and water damage.

Notably, hardwood cabinets have a significantly prolonged lifespan. These robust structures can endure for decades, sharply contrasting with the brief few years offered by particle boards.

• The Value of Strategic Planning and Expert Consultation

Cabinet design necessitates comprehensive planning and judicious cost considerations. One should deliberately consider where it’s feasible to cut costs without compromising on durability or aesthetics.

Moreover, consultation with professionals who provide custom cabinets can prove instrumental in navigating these considerations. They can advise about the optimal wood type for your specific needs based on diverse factors, including location, usage, vulnerability to water, etc.

• Recommendation and References

Based on personal experience, hardwood cabinets are indeed an invaluable investment, especially when considering durability.

For further understanding of the differences between particle board and hardwood cabinets, check out this reference from the University of Massachusetts, Amherst link. As always, consulting with professionals and making informed decisions is crucial.

Factors Impacting Water Damage in Particleboard

• The Role of Humidity and Water Vapor

Water damage in particleboard does not solely result from direct contact with water. Even exposure to high levels of humidity and water vapor can result in significant damage.

• Impact of Particleboard Composition

Particleboard is a composite material made up of wooden particles and binding materials.

Several factors from the composition, such as the type of binding material, the nature of the wooden particles, fabrication methods used, the age of the board, as well as its density, can have a measurable influence on its resistance to water-related damage.

• Influence of Surface Treatment

Surface treatments on particleboards, such as applying veneers, laminates, paint, or paper, play a significant role in their resistance to water damage. These treatments act as a barrier between the particleboard and water and can limit the extent of damage to a notable degree.

• Comparing the Effects of Direct Water Contact and Humidity Exposure

Direct exposure to water proves to be significantly more damaging for particleboards than mere exposure to humidity or water vapor.

• The Role of Exposure Duration and Additional Stress

The duration of water exposure and the presence of any additional stress on the particleboard can directly influence the level of damage sustained.

• Types of Damage

Water damage on particleboards can manifest in various forms. These include noticeable color change, removal of surface layers, swelling, bending, destruction of the material, and even growth of harmful fungi like mold.

• An Experimental Study on Water Exposure and Particleboard Drying

In an attempt to understand the behavior of particleboard underwater exposure, research was conducted. Researchers noted that the first few hours of water exposure are critical.

If the board is withdrawn from the water during this initial phase, it can return to its original thickness. However, if left undisturbed for approximately 6 hours, the damage becomes irreversible.

After 24 hours, the particleboard attains maximum thickness, regardless of being submerged in water for longer periods. The drying of the particleboard is a slow process; it takes approximately two weeks for the board to reach its new dry thickness.

• The Efficiency of Water-Resistant Protection

Applying water-resistant protection, such as high-quality paint, can effectively slow down the absorption of water by the particleboard and thus lessen the extent of potential damage.

• Significance of Timely Measures and Protective Measures

Prompt action and the application of protective measures are of paramount importance. It can significantly help mitigate the extent of damage caused by water exposure to particleboard.

In conclusion, awareness and understanding of the aforementioned factors can significantly help in minimizing the destructive effects of water exposure in particleboards.

Anyone dealing with particleboards – such as furniture manufacturers, builders, and distributors – would benefit from ensuring to account for these factors in their projects.

For further reading, the University of Tennessee’s Agricultural Extension offers several detailed articles on wood-based composites and their best usage practices.

Characteristics of Particle Board

Particle board is an economical material composed of waste wood particles, sawdust, and shavings. However, its vulnerability to moisture damage makes it less durable compared to solid wood products.

• Where to Install Particle Board

When considering the use of particle board in your home or office, ensure it’s installed in areas with minimal moisture contact. It’s not advisable to use it under sinks or as a part of backsplashes, as excessive moisture exposure can degrade the board’s quality.

• The Use of Screws or Nails in Particle Board

In installing or repairing, one must be wary of using screws or nails in particle boards. These fasteners can create entry points for moisture, hastening the deterioration of the board. Thus, it’s best to choose adhesives suitable for bonding particle boards.

• Dealing with Water-Damaged Particle Board

Should the particle board fall victim to water damage, often the best course of action is to replace it promptly? Delaying replacement could lead to a host of problems including mold growth, staining, and warping, not to mention a significant loss in strength.

• Repairing Water-Damaged Particle Board

In situations where the water damage is minimal and replacement isn’t immediately necessary, the damaged particle board may be repaired.

It is crucial to dry the wood thoroughly before proceeding with the repair. Sanding should be done to smooth out the rough spots, followed by the application of wood filler to fix any holes or cracks.

• Speeding Up the Drying Process for Wet Particle Board

The drying process for a damp particle board can be challenging, but there are ways to hasten it. One such method is to use a hairdryer in a moderate setting to speed up evaporation.

• Cleaning Particle Board to Kill Mold

While prevention is better than cure, sometimes mold growth may occur on your particle board. In such cases, cleaning the board with distilled white vinegar can kill the mold and prevent further growth. This routine cleaning process will help extend the life of your particle board.

• Rectifying Warped Particle Board

If warping does occur, don’t panic. There are a couple of corrective measures you can take. You can flatten the warped particle board using a planer, although this will thin the board. Alternatively, you can wrap the warped board with a damp towel and leave it under the sun to flatten naturally.

• Life Expectancy of Particle Board

In terms of life span, particle board lasts around five to ten years in an environment with minimal exposure to moisture and stable temperatures. However, this lifespan may be shortened if the board encounters frequent temperature variations and excessive moisture.

Remember, the longevity of your particle board largely depends on how well you maintain it. For more information on care methods, you may visit this link that explains in detail how particle boards can be well maintained.

Being familiar with the properties of your particle board and maintaining it accordingly is the key to its longevity.

• Identifying and Fixing the Source of Water Damage

The key to preventing future water damage is pinpointing and rectifying the source. It’s important to thoroughly inspect your home to identify the source of the water damage. This could be a roof leak, burst pipes, or even condensation build-up.

By fixing these issues early, you can avoid extensive and costly damage in the future. For more comprehensive information about dealing with water damage, the Federal Emergency Management Agency provides a useful guide.

• Potential Sources of Water Damage

Water damage in a home typically originates from a few common sources. Burst pipes are a major culprit, particularly in colder months when water can freeze, expand, and cause the pipes to crack.

Likewise, roof leaks are another common troublemaker, often due to worn-out shingles or improper sealing. Timely detection and repair of these sources can nip the problem in the bud.

• Hiring a Restoration Company

In cases of extensive water damage, consider contacting a professional restoration company. These experts possess the necessary equipment and experience to restore your home to its pre-damage state effectively.

• Drying Particle Boards before Repair

When water damage affects particle boards, the repair process begins with drying them out completely. Lingering moisture can result in mold or mildew formation, accelerating the deterioration of the board.

• Removing Excess Water and Expedited Drying

You can speed up the drying process by using a hairdryer and towels to remove any excess water. Its crucial not to rush this process to ensure the board is completely dry before moving forward.

• Sanding Swollen Areas

If the particle board has swollen areas, you can use sandpaper to level it out. Sand the swollen areas until they are flush with the rest of the board, then you can remove the damaged sections.

• Cutting Out Damaged Areas

Once the board is level, you can use a knife or another sharp tool to cut out the damaged areas. This step needs to be carried out diligently and carefully, making sure not to inflict further damage on the board.

• Filling Holes with a Wood Filler

Following the removal of damaged areas, you can use wood filler to fill any holes left behind. Apply the filler with a putty knife and smooth out any excess for a seamless finish.

• Using Sandpaper for Smoothness

Following the filler application, use sandpaper to level the surface again. This ensures a smooth and even finish, preparing the board for the finishing coat.

• Applying a Finishing Coat

A finishing coat can be applied to give furniture or cabinets a new lease of life. This refreshes the look of the particle board and offers a level of protection against future damage.

• Replacing Particle Board

If the repair process proves too time-consuming or ineffective, replacing the particle board might be your best move. Remember, the goal is to rectify the damage effectively and prevent future occurrences.

• Contacting Restoration Specialists

For extensive water damage that affects more than just the particle board, don’t hesitate to contact a professional restoration company.

Their expertise can save you time, money, and further damage down the line. Remember, water damage can lead to structural instability and mold growth, which could pose serious health risks.

I hope you found this guide helpful. Dealing with water damage can be a daunting task, but with the right approach and tools, it can be successfully managed.

Be proactive, take the necessary steps for repair, and most importantly, take preventive measures to avoid repetitive damage in the future.